High Speed Fully Automatic Complete Production Line Small Scale Bathroom Toilet Tissue Paper Roll Making Machine Price In China

This toilet paper rewinding machine can rewind jumbo toilet paper roll into various small diameters without changing its width. The diameter and tightness of finished toilet rolls can be easily adjusted by change the settings on control panel, and output paper rolls are ready for cutter.

This toilet paper rewinder adopts AC frequency conversion stepless speed regulation, which can running stably while customers change its speed.

This machine has PLC system and a Human Machine Interface control panel so that one person can operate it very easily. It is an ideal machine for small toilet paper product making plant.

| Model | YB-1880 | YB-3000 |

| Jumbo roll width(mm) | ≦2200mm | ≦3000mm |

| Core size of raw paper | 76.2mm | |

| Diameter of finished product | 90-250mm (Other Size to be Specified) | |

| Core size of finished product | Φ 32-50mm | |

| Perforation Distance | 100-150mm (Other Size to be Specified) | |

| Tail trimming and sealing | overall cut, tail sealed beautifully and reliably; Storage tank to hold glue | |

| Main driving | Frequency conversion speed regulation 7.5-15KW 380V,50HZ | |

| Core tube: | Automatic core loading | |

| Pitch of perforation | 6 Blades, 110mm | |

| Parameter set-up | HMI | |

| Machine speed | 0-300m/min | |

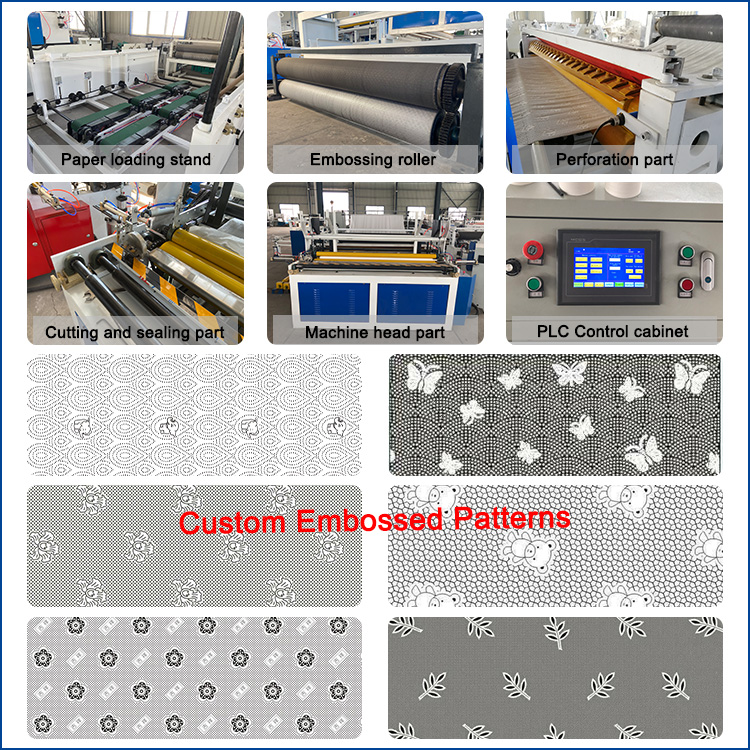

| Embossing Unit | Steel to rubber/steel to steel/steel to wool embossing | |

| Air -system | 3HP air compressor, min. pressure 5kg/cm2pa ( provide by user) | |

| Mechanical driving | Driving by stepless gear box | |

| Weight | 3T | 4T |

| Lamination Unit | Can be Ordered | |

Four-roller automatic feeding→synchronous conveying→embossing→punching→automatic winding→cutting→packing→sealing.

1. Rewinding---The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper---The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length

required by the customer.

3. Packaging---Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet paper are packaged and sealed by a sealing machine.

1. Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.

2. Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing.

3. The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs.

4. Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5. Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism

-

Small business idea table napkin tissue paper m...

-

7L Automatic Facial Tissue Paper Making Machine...

-

Semi-automatic Napkin making machine production...

-

Factory Price Embossing Box-Drawing Soft Facial...

-

6 lines facial tissue paper machine automatic t...

-

1575 Semi automatic toilet tissue roll rewindin...