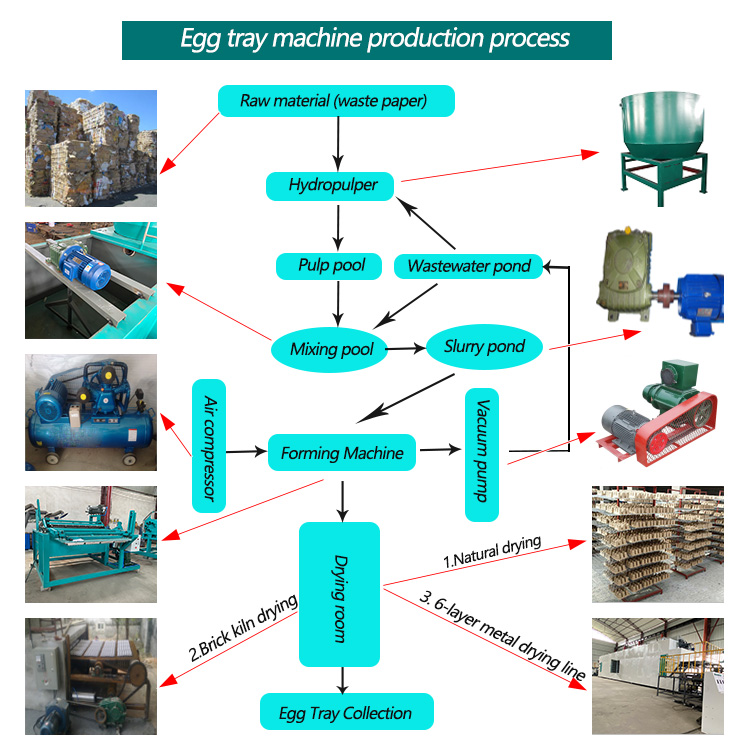

Young Bamboo pulp molding automatic egg tray production line mainly uses waste paper as the raw material, which has rich sources and low prices, and is a comprehensive development and utilization of waste. The water used in the production process is closed and recycled, no waste water or waste gas is discharged. After the pulp molding products are used, the waste can be recycled like ordinary paper. Even if it is abandoned in the natural environment, it is easy to rot and decompose into ordinary paper. Organic substances are completely environmentally friendly products. The waste paper is added to the pulper and water is sent to the storage tank. The pulp in the storage tank is evenly transferred to the supply tank with a mixer. The pulp in the supply tank is stirred to a certain concentration and sent to the molding machine. The molding machine produces an egg tray to Conveyor belt. The conveyor belt passes through the drying line to dry the egg tray, and finally it is collected and packed. In addition, the vacuum pump can pump the unused water in the molding machine to the backwater tank. The backwater tank can transport water to the pulper and the pulp storage tank, and the water can be recycled.

The raw materials are mainly from various pulp boards such as reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, and waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. Waste paper, widely sourced and easy to collect. The required operator is 5 people/class: 1 person in the pulping area, 1 person in the molding area, 2 people in the cart, and 1 person in the package.

|

Machine Model

|

1*3

|

1*4

|

3*4

|

4*4

|

4*8

|

5*8

|

5*12

|

6*8

|

|

Yield(p/h)

|

1000

|

1500

|

2500

|

3000

|

4000-4500

|

5000-6000

|

6000-6500

|

7000

|

|

Waste Paper(kg/h)

|

80

|

120

|

160

|

240

|

320

|

400

|

480

|

560

|

|

Water(kg/h)

|

160

|

240

|

320

|

480

|

600

|

750

|

900

|

1050

|

|

Electricity(kw/h)

|

36

|

37

|

58

|

78

|

80

|

85

|

90

|

100

|

|

Workshop Area

|

45

|

80

|

80

|

100

|

100

|

140

|

180

|

250

|

|

Drying Area

|

No need

|

216

|

216

|

216

|

216

|

238

|

260

|

300

|

2.Power means the main parts,not include dryer line

3.All fuel use proportion are calculated by 60%

4.single dryer line length 42-45 meter,double layer 22-25 meter,multi layer can save workshop area

-

YB-1*3 egg tray making machine 1000pcs/h for bu...

-

Automatic paper pulp egg tray production line /...

-

Young Bamboo paper egg tray making machine auto...

-

Automatic waste paper pulp egg tray making mach...

-

1*4 waste Paper Pulp Molding Drying Egg Tray Ma...

-

Egg Tray Pulp Molding Making Machine for Small ...