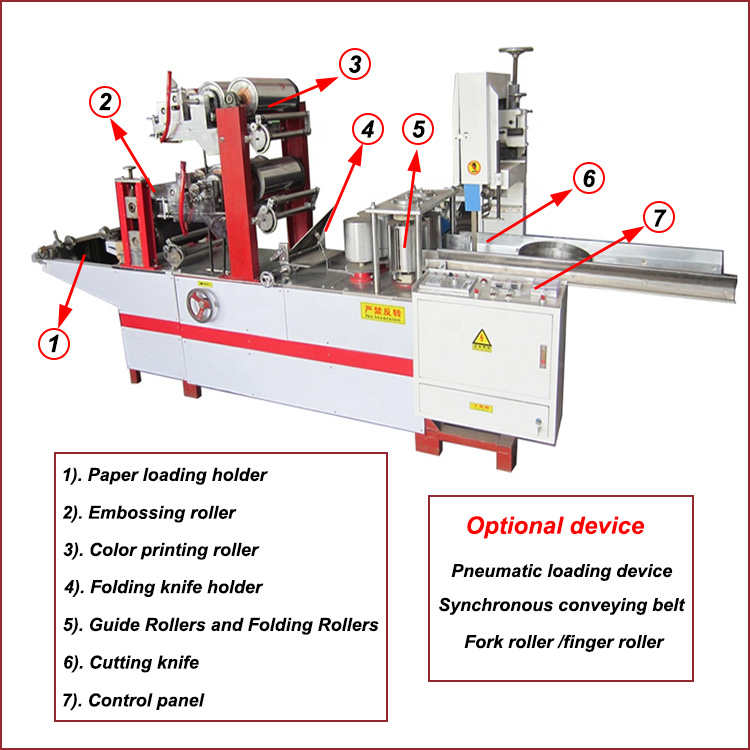

Young Bamboo napkin tissue machine,This machine is mainly for producing folded rectangle or square type napkin paper through smooth compressing, color printing and embossment. this machine is mounted with two-color water printing ink system, which can print various beautiful logo or patterns. it possesses features, such as, clear embossment, correct overprinting and stable running under high-speed. it is the specialized equipment for making high-rank napkin paper.

Napkin Making Machine Product Details

| Machine Mode | YB-220/240/260/280/300/330/360/400 |

| Unfolding Size | 190*190-460*460 mm (also customization available) |

| Folded size | 95*95-230*230mm |

| Raw paper Size | ≤φ1200 |

| Raw paper Core inner dia | 75mm Standard(Other size are available) |

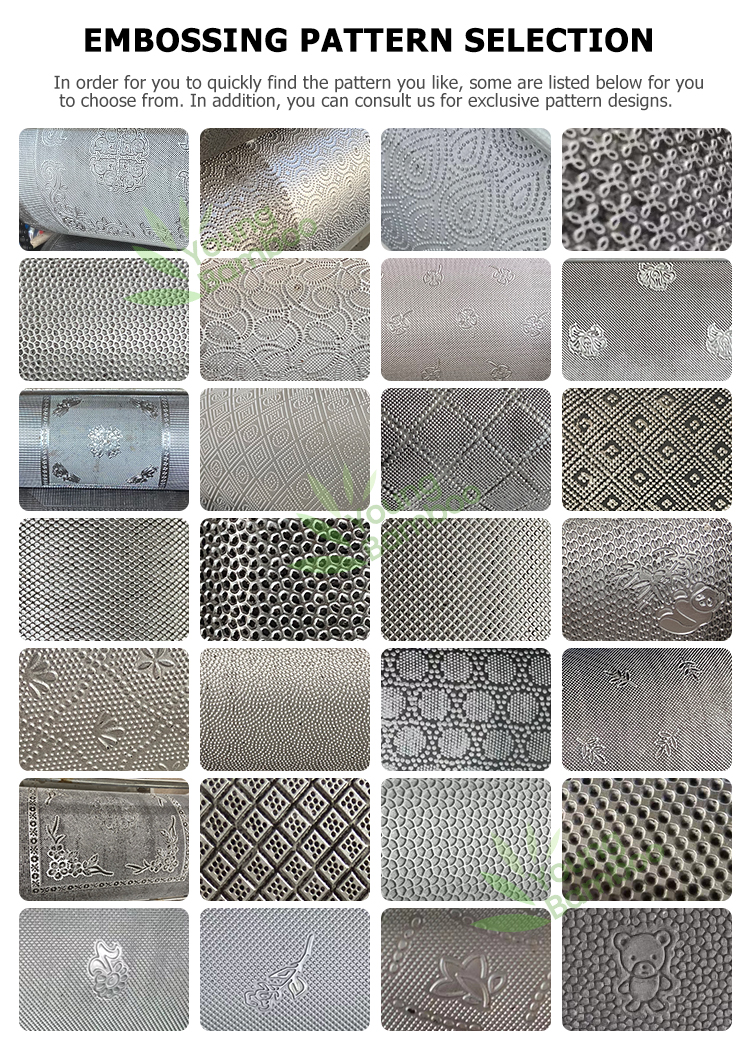

| Embossing Roller end | Cots,wool roll |

| Counting System | Electronic Counting |

| Power | 4.2KW |

| Dimensions | 3200*1000*1800mm |

| Weight | 900KG |

| Speed | 0—800 pcs/minute |

| Use of power | Frequency Control ,electyomagnetic governor |

| Transmission | 6 Chains |

| Space Required | 3.2-4.2X1X1.8m |

1. Adopt flexible printing unit, high procession ceramic anilox roller, making the water ink equally spread and print out extract and stereo pattern.

2. Raw material through synchronous belt and come into calendaring unit, and into embossing unit. There is tension unit between raw material and calendaring, raw material and embossment.

3. Folding wheel automatic stop machine protection unit.

4. Automatic rectify system.

5. Automatic constant temperature drying system.

6. Raw material broken protection unit. Automatic speed down unit when raw material run out. Folding roller stop protection unit.

7. Water ink circulation system.

8. Full-automatic unreel control system: track the speed of main machine by computer, transmit to servo system, the servo system convey paper to printing system accurately according to the order of computer and make perfect product.