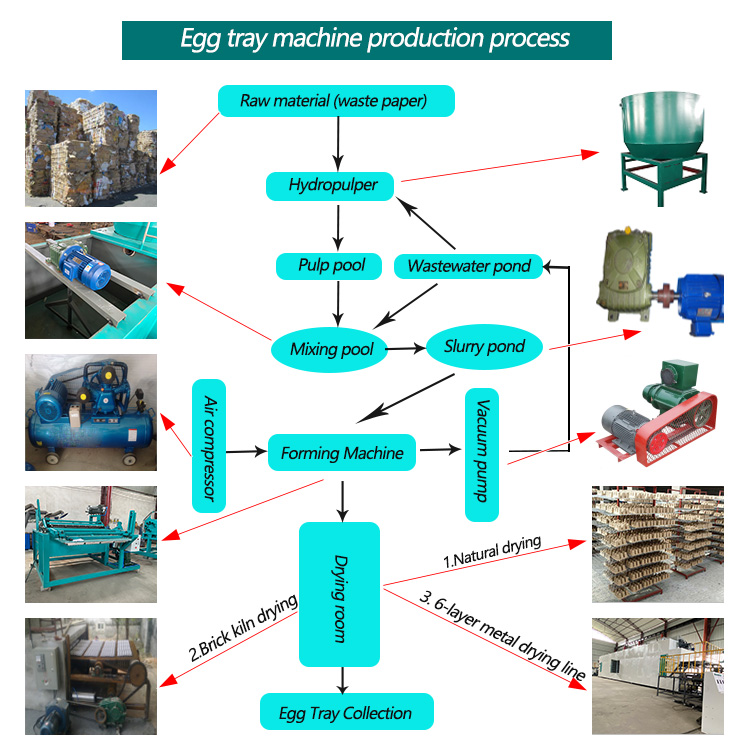

Egg Tray Production Line processing makes use of recycled water and does not lead to water or air pollution.Finished packaging products can be recycled after being used in storage, transport, and sales. After shredding, they easily decompose, even if discarded into a natural environment.Egg Tray Production Line, which uses waste paper, cardboard, leftover material of paper mill, by hydropulper, mix making acertaindense pulp, and pulp is absorbed by vacuum of special metal moulding to become wet products, through drying , and shaping to become finished products.

The raw materials are mainly from various pulp boards such as reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, and waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. Waste paper, widely sourced and easy to collect. The required operator is 5 people/class: 1 person in the pulping area, 1 person in the molding area, 2 people in the cart, and 1 person in the package.

|

Machine Model

|

1*3

|

1*4

|

3*4

|

4*4

|

4*8

|

5*8

|

5*12

|

6*8

|

|

Yield(p/h)

|

1000

|

1500

|

2500

|

3000

|

4000-4500

|

5000-6000

|

6000-6500

|

7000

|

|

Waste Paper(kg/h)

|

80

|

120

|

160

|

240

|

320

|

400

|

480

|

560

|

|

Water(kg/h)

|

160

|

240

|

320

|

480

|

600

|

750

|

900

|

1050

|

|

Electricity(kw/h)

|

36

|

37

|

58

|

78

|

80

|

85

|

90

|

100

|

|

Workshop Area

|

45

|

80

|

80

|

100

|

100

|

140

|

180

|

250

|

|

Drying Area

|

No need

|

216

|

216

|

216

|

216

|

238

|

260

|

300

|

2.Power means the main parts,not include dryer line

3.All fuel use proportion are calculated by 60%

4.single dryer line length 42-45 meter,double layer 22-25 meter,multi layer can save workshop area

Egg carton making machine

Eggs, duck eggs, goose eggs, quail eggs, etc. can all be packaged with this machine. Young Bamboo Specializing in the production of 10, 12, 15, 18 egg carton products. Molded egg tray forming machines can help poultry farmers store eggs. You can add additives during the production process to protect the eggs from the invasion of germs. This is very necessary because eggs are most easily eroded by bacteria during storage.

Paper apple tray machine

Fruits are easily devalued due to bumps. 2/4/12 apple trays can reduce the occurrence of this situation. Round fruits such as strawberries and oranges can be protected by the fruit tray machine. Fruits packed in fruit trays are a good choice whether they are displayed on supermarket shelves or as gifts to others.

Coffee Cup Tray Making Machine

Catering industry usually uses 2/4 drink trays to hold coffee, milk tea, juice and other drinks. The pulp coffee tray has a better supporting effect and can keep the drink stable. Some of our customers said that coffee cup holder tray making machines can play an important role in the takeaway business.

Shoes Tray Making Machine

Shoe trays have been widely used in the shoe industry. Paper pulp shoe tray not only has a good supporting effect but also has a moisture-proof effect. Our shoe supports can be tailored to specific shapes.

-

Waste Paper Recycling Egg Carton Box Egg Tray M...

-

YB-1*3 egg tray making machine 1000pcs/h for bu...

-

1*4 waste Paper Pulp Molding Drying Egg Tray Ma...

-

Fully automatic egg tray making machine egg dis...

-

Young Bamboo paper egg tray making machine auto...

-

Automatic waste paper pulp egg tray making mach...