| Model | YB-1*3 | YB-1*4 | YB-3*4 | YB-4*4 | YB-4*8 | YB-5*8 | YB-6*8 |

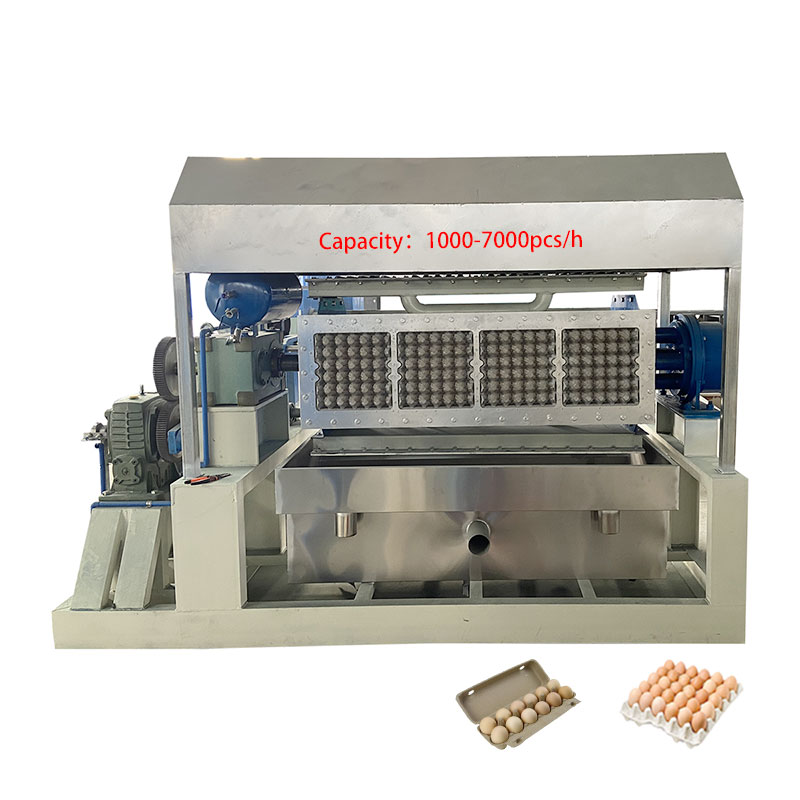

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

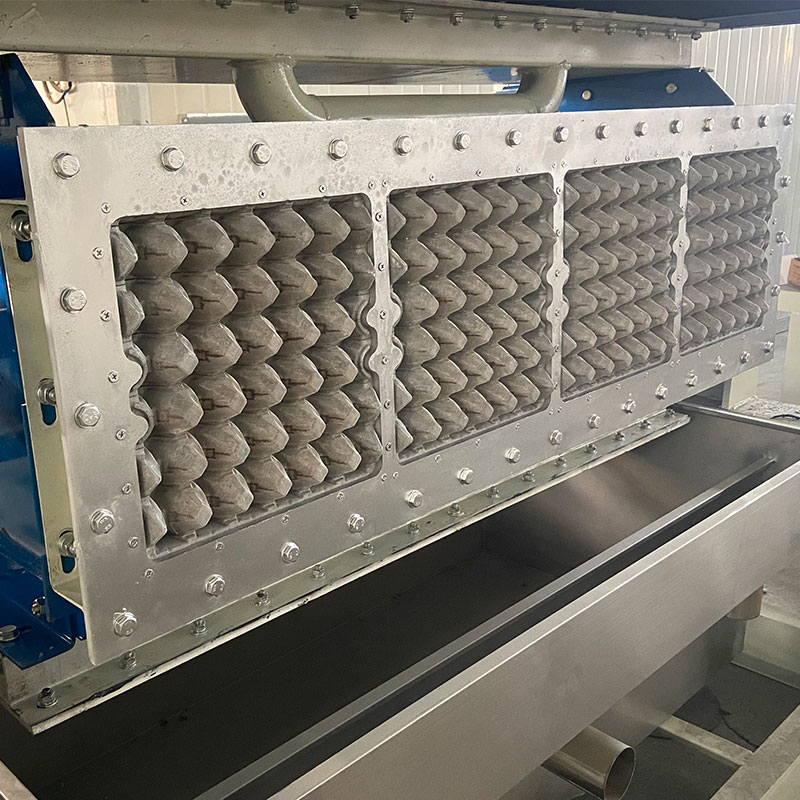

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kw) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

1. The host adopts Taiwan gear divider technology to achieve the operating accuracy of the equipment with 0 errors.

2. The main machine base of the egg tray machine adopts thickened 16# channel steel, and the drive shaft is precision machined with 45# round steel.

3. The main engine drive bearings are all made of Harbin, Watt, and Luo bearings.

4. The host positioning slide is welded with 45# steel plate after heat treatment.

5. Slurry pumps, water pumps, vacuum pumps, air compressors, motors, etc. are all made of domestic high-quality brands.

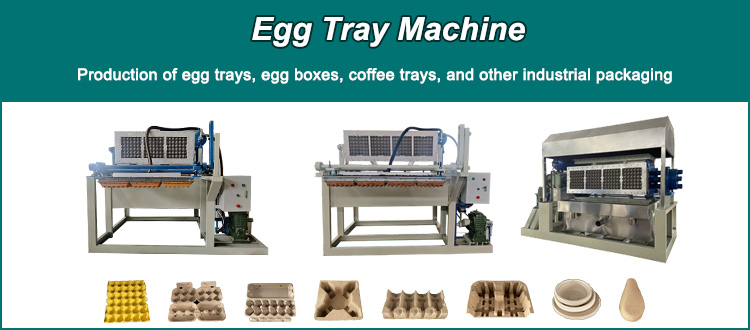

Sample of Egg Tray Making Machine

Remarks:

★. All equipment templates can be customized in size according to actual customer requirements.

★. All equipment is welded with national standard steel.

★. Important transmission parts can be driven by imported NSK bearings.

★. The main engine drive reducer adopts heavy-duty high-precision reducer.

★. The positioning slide adopts deep processing, anti-wear and fine milling.

★. The whole machine motor is all domestic first-line brands, guaranteed to be 100% copper.

★. Protective measures are adopted for electrical appliances, machinery, pipelines, etc. to extend the service life.

★. Provide customers with detailed equipment layout plans and use drawings for free.

More Details

The 4x4 egg tray machine is a drum-type machine with 4 plates forming molds and 1 plate transferring abrasive tools. It produces 3000 pieces of equipment at a time. The length of the template is 1500*500mm, and the effective size of the mold is 1300*400mm. It can produce environmentally friendly pulp products such as egg trays, egg cartons, coffee trays, fruit trays, bottle trays, electronic toolkits, lining and industrial packaging.The number of mold closing times in one minute is 12-15 times, and 4 egg trays can be produced on one board (other products are calculated according to the actual size).

This machine is equipped with a speed-regulating motor and an indexer, with adjustable speed and easy operation.The required operators for this egg tray equipment model are 4-5 people: 1 person in the beating area, 1 person in the forming area, and 2-3 people in the drying area.The main raw materials are book paper, newspapers, cartons, all kinds of waste paper, waste paper scraps from carton factories and packaging factories in printing plants, tail pulp waste from paper mills, etc.

-

YB-1*3 egg tray making machine 1000pcs/h for bu...

-

Automatic paper pulp egg tray production line /...

-

Fully automatic egg tray making machine egg dis...

-

Waste Paper Recycling Egg Carton Box Egg Tray M...

-

Young Bamboo paper egg tray making machine auto...

-

Egg Tray Pulp Molding Making Machine for Small ...